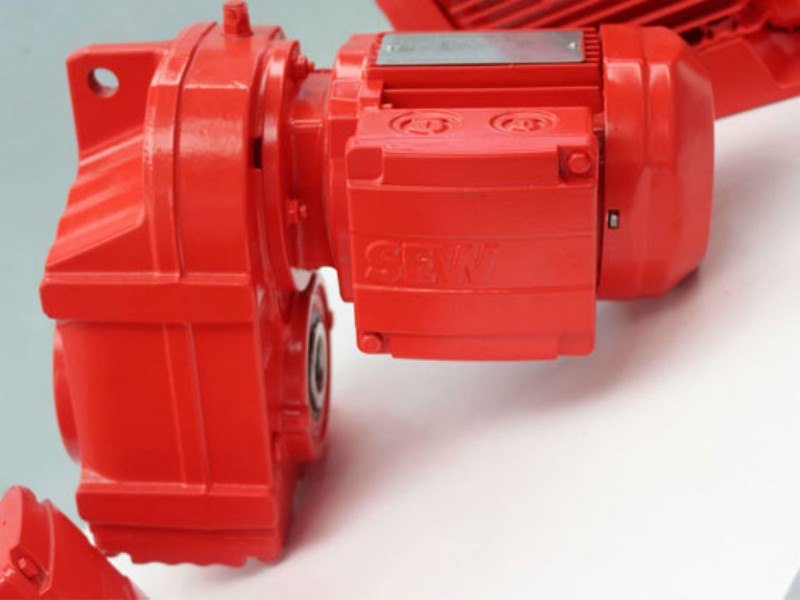

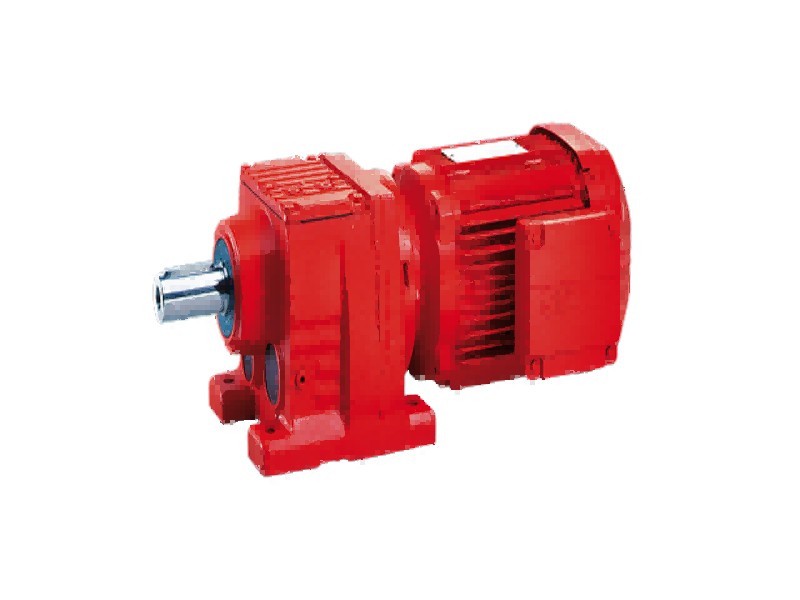

SEW gear units can be used flexibly. Be it for a specific customer solution or a standard application. Select your gear unit from a wide assortment. The right size, power, gear ratio, the right torque as well as design and surface. Tailored to your application requirements and to your area of application.

Application of SEW Motor

Application of mechanical fault protection brake

Various specifications of the conveyor belt

Promote applications

Applications that require control accuracy

Integrate or install encoder positioning tasks

Can be used in various industries around the world

Features

Comprehensive braking concepts and combinations, ie, motor sizes within this range correspond to up to three different brake sizes

Cost-optimized built-in encoder integrated in the motor

Save time by optimizing motor selection, order processing and logistics processes

IE1~IE4 efficiency motor

Compact design saves space and costs

Facing the future, same environmental protection (standard)

Use energy-saving motors to reduce operating costs; our energy-saving motors meet efficiency levels

Standard Efficiency (IE1)

High efficiency (IE2)

High efficiency (IE3)

Extremely high efficiency (IE4)

"Global Motors" incorporates a number of energy efficiency specifications and rules in one design.

Support Global Standards and Specifications

Specification

| Technical data | ||

| Gear unit reduction ratio | [i] | 3.77 to 281.71 |

| Multi-stage gear unit reduction ratio | [i] | 87 to 31434 |

| Output torque | [Nm] ([in-lb]) | 87 to 18000 (770 to 159300) (also in reduced backlash version) |

| Motor power range | [kW] ([hp]) | 0.12 to 200 (0.16 to 268) |

CASE

At Sinoko Crane, we don't just provide high-performance components—we deliver complete lifting solutions tailored to your operation's demands. Our SEW-Eurodrive gear motors have been successfully integrated into numerous crane systems across industries, helping customers improve reliability, efficiency, and service life. Explore one of our recent crane spare parts projects to see how our solutions perform in action.

30T C-Hook Deployment for Copper Producer in Ecuador by Sinoko Cranes

Sinoko C-Hooks cut Ecuador copper coil damage to 0%! 30T capacity, 150°C heat-resistance & EdgeGuard™ jaws boost throughput 50%. Get coil lifting solutions now!

Learn More Get a QuoteInstallation of QZ-Type Grab Bucket Bridge Crane Project Case

The Sinoko QZ-Type Grab Bucket Bridge Crane was specially designed for a Brazilian client as a grab bucket crane, which significantly improved the client's work efficiency and received unanimous praise from the client.

Learn More Get a Quote32T Steel Coil Handling Crane Project Case

Sinoko Crane with years of experience in crane manufacturing and design, the steel coil handling crane has helped customers reduce costs and improve the efficiency of steel coil transportation.

Learn More Get a QuoteFAQs

SEW‑Eurodrive gear motors feature precision helical‑bevel gear units achieving efficiencies above 96 %. These modular units, paired with optional IE1–IE4 energy‑efficient motors, deliver long, maintenance‑free operation while reducing running costs.

This gear motor supports a wide range of crane applications—including overhead, gantry, jib, magnet, grab, and free‑standing cranes—making it a flexible, all‑around solution for diverse lifting scenarios.

It offers broad customization: reduction ratios from about 3.77 up to 28,434, torque outputs ranging 87 Nm to 18,000 Nm, and motor power from 0.12 kW up to 200 kW. This adaptability ensures optimal match for both light and heavy‑duty crane needs.

Yes—SEW‑Eurodrive products can include built‑in mechanical protection brakes and encoders for positioning. You can choose from different brake sizes and encoder options to enhance control precision and safety.

Thanks to a streamlined selection process and optimized motor choice, Sinoko’s SEW‑Eurodrive gear motors simplify ordering, delivery, and inventory—a time‑saving and cost‑effective advantage for crane operators.

These gear motors support global standards and environmental specifications. They share common design elements and surface finishes across IE1–IE4 efficiency levels, ensuring compliance and future‑proof compatibility worldwide.